Choosing the right head studs for better engine performance

We have launched our own HCR Head Stud Sets (11mm and 14mm) and for better performance results we improved the design of this product.

Mixing our experience and knowledge with an endless desire to improve and invent better solutions for higher engine performance and reliability, we have launched our own HCR Head Stud Sets of 11mm and 14mm threads. We have improved the design of this product to be able to provide our clients with the best head studs for clamping the cylinder heads onto the block assembly to reduce the risk of having a head lift under a higher boost. It all took a considerable amount of our time and other resources, but it paid off.

Our studs differ from others available in the market. There are a couple of features implemented in the design of studs that provide better performance results.

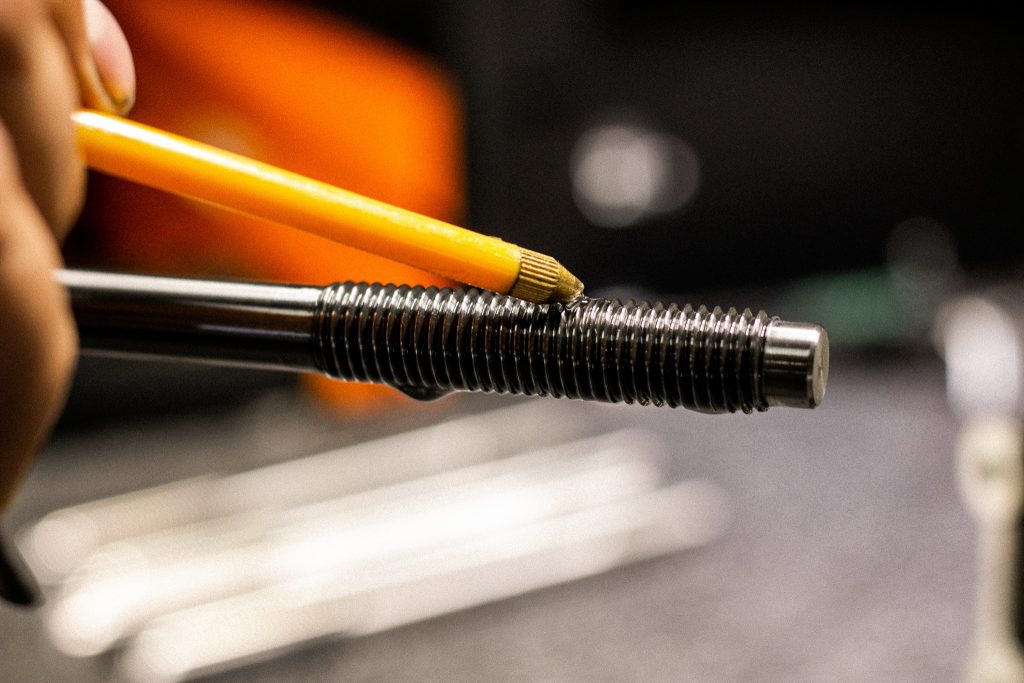

Our studs come with dog-points. It allows studs to bottom out in a controlled way and provides good distribution along the thread allowing the lower thread to take some of the load before we put tension on the upper part of the block thread. In other words, when tightening studs to a higher tension you are less likely to be able to pull the threads out of your block and damage it.

In collaboration with Latvia University of Life Sciences and Technologies, we ran a series of tests where with a tensile strength testing machine we compared studs from different manufacturers that are available in the market, including our design. As you already might know, studs are designed to stretch, which plays a valid role in clamping the joint together. We found that before yielding each stud stretches differently from another and that our studs provide more clamping force and higher yield point than compared to other studs on the market. In other words, our studs can achieve a larger clamp force in comparison before yielding, tensile strength is up to 230,000 psi, shown below.

We also studied studs used by World Rally Championship (WRC) cars and found that the shank of the stud is turned down and it is thinner than into the thread range, which allows us to control the stretching into their elastic range. This aspect significantly affects the strength of the stud. During the test where we searched for a yielding point, we found that our stud stretched 3 times more than other known manufacturer studs.

In summarising, we recommend choosing the right head studs for your engine wisely. It is not always about “the bigger the better”, it is more about clamp load, how your studs can deal with it and what is your aim, regardless of thread size. Our HCR 11mm Head Stud Set will be a great solution for the street car enthusiast who plans to see up to around 550hp. We can offer them at a better price than others, ensuring that it will work as well as others and even better. If you plan to go for more power starting from 500+hp we recommend replacing the conventional 11mm threads with a series of 14mm precisely manufactured. These studs have proven themselves on the tests we ran. We also have received good reviews from our clients who already use our head studs. All this convinces us that we can provide the best solution that is available on the market.

Find HCR head studs in our shop here.

HCR Head Stud Install Instructions

Follow step-by-step instructions for installing HCR 14mm Head Studs:

1. Lubricate the studs block end threads with engine oil or assembly lube.

2. Screw the studs in the block to approx. 10Nm (hand tight with 3/16 allen wrench).

If any resistance is felt – stop! If you experience resistance, back out the stud and inspect the threads on both parts; clean the threads as needed. Try threading it again.

3. Verify stud height relative to each other stud. If everything is done right, all studs should be +/- 0,3mm relative height to each other.

4. Install the head gasket and supply a torque lube all around the top of the threads.

5. Install the cylinder head. Be sure that both surfaces of the washer and cylinder head are degreased.

6. Apply torque lube to flange part of the head stud nut and install it.

7. Follow this torque procedure:

| Step NR | Center two | Outer four |

| Step 1 | 55Nm | 40Nm |

| Step 2 | 115Nm | 95Nm |

| Step 3 | 155Nm | 150Nm |

| Step 4 | 175Nm | 175Nm |

| Step 5 | Check if all studs are tight! | |

HCR 14mm Head Studs are suitable for all Subaru EJ20/22/25 series engines. We have improved the design of the threads and tested it, to make sure that we can provide the best solution for clamping the cylinder heads onto the block assembly to reduce the risk of having a head lift under a higher boost. Learn more about the improvements here.

Follow step-by-step instructions for installing HCR 11mm Head Studs:

1. Lubricate the stud’s block end threads with engine oil or assembly lube.

2. Screw the studs in the block to approx. 10Nm (hand tight with 5mm allen wrench).

If any resistance is felt – stop! If you experience resistance, back out the stud and inspect the threads on both parts; clean the threads as needed. Try cleaning threads.

3. Verify stud height relative to each other stud. If everything is done right, all studs should be +/- 0,3mm relative height to each other if everything is done right.

4. Install the head gasket and apply torque lube to all around the top of the threads.

5. Install the cylinder head. Be sure that both surfaces of the washer and cylinder head are degreased.

6. Apply torque lube to flange part of the head stud nut and install it.

7. Torque the heads to 120Nm in 3 equal steps (40Nm, 80Nm, 120Nm), from middle to outside.

HCR 11mm Head Studs are suitable for all Subaru EJ20/22/25 series engines. We have improved the design of the threads and tested it, to make sure that we can provide the best solution for clamping the cylinder heads onto the block assembly to reduce the risk of having a head lift under a higher boost. Learn more about the improvements here.

YOU’RE done! Thank You for respecting your engine!

Three reasons why your Subaru engine might fail you

How to go racing with your Subaru not worrying that you will need a lift home from some stranger with a car trailer? You have to consider that there are 3 main reasons why your Subaru engine with increased power might fail you:

- 1.LEAKING OR BLOWN HEAD GASKET

- 2.CRACKED CYLINDER WALLS FROM HIGH PRESSURE OR BOOST

- 3.SPUN ENGINE BEARINGS AND LOSS OF OIL PRESSURE

We had the same problems with our Subaru many years ago when we started looking for some help to prevent the same problems mentioned before. But there was no one who could give us some convincing solutions. This led us to find it by ourselves – and you know what? Not only that we found the solutions, but we also tested and boosted our experience by maintaining more than 300 engine blocks that have improved projects in Europa.

Why are your cylinder walls cracking, and your head gasket is leaking? The answer is – cylinder walls are not supported enough.

For open decks, there are only two supporting tabs for each cylinder or four supporting tabs for semi-closed decks. If you push your engine hard, cylinder walls are going to move under high cylinder pressures. To prevent it you need to support the cylinder walls and it is commonly called CLOSED DECKING.

Closed decking is a process where the top plane of the engine case is machined so that it can accept CNC machined inserts. After this process, cylinder walls are completely supported in the weakest place – at the top, where combustion happens, and proper support is needed when BANG happens. All the coolant bores that exist in the head gasket are machined in-cylinder supporting inserts, so engine cooling is not affected. An extra cooling passage is machined for stages 2 and 3 so the engine coolant flows freely under the head gasket.

We provide closed decking for all EJ engine series in three stages and other manufacturer engines. Learn more here.

Why are your engine bearings failing?

EJ engines are often considered to have weak main bearings that lead them to oil pressure problems and both main and rod bearing failure. The truth is that bearings themselves are as good as any other engine manufacturers would have. If you own a Subaru EJ block, then there is almost a 100% chance that the main bearing bore alignment is out of line. To correct it we do vertical CNC line boring.

- 1.We start by removing as little material as possible from each of the case halves depending on how much the bores are out of alignment from each other;

- 2.Then we bolt the cases together;

- 3.And after that, we align the case very precisely against the CNC spindle axis after which the line boring process within a precision of 5 microns are made

This prevents bearing from failing caused by incorrect clearances. To keep these clearances stable under high loads next step is mains pinning.

High boost and high cylinder pressure applications cause distortion and flex in Subaru EJ series engine cases which shortens bearing life. Machining pins to the Subaru case main webs reduce distortion and flex caused by both situations. Mains pinning is done before case assembly for line boring, so newly straightened cases are ready to go for final assembly after machining is done.

These are the solutions we have found and tested. Now you know how to make really Hard Core for your engine: closed deck + line bore + mains pinning is a MUST. It will keep you away from troubles and save some time and nerves.

Stay safe & respect your engine!