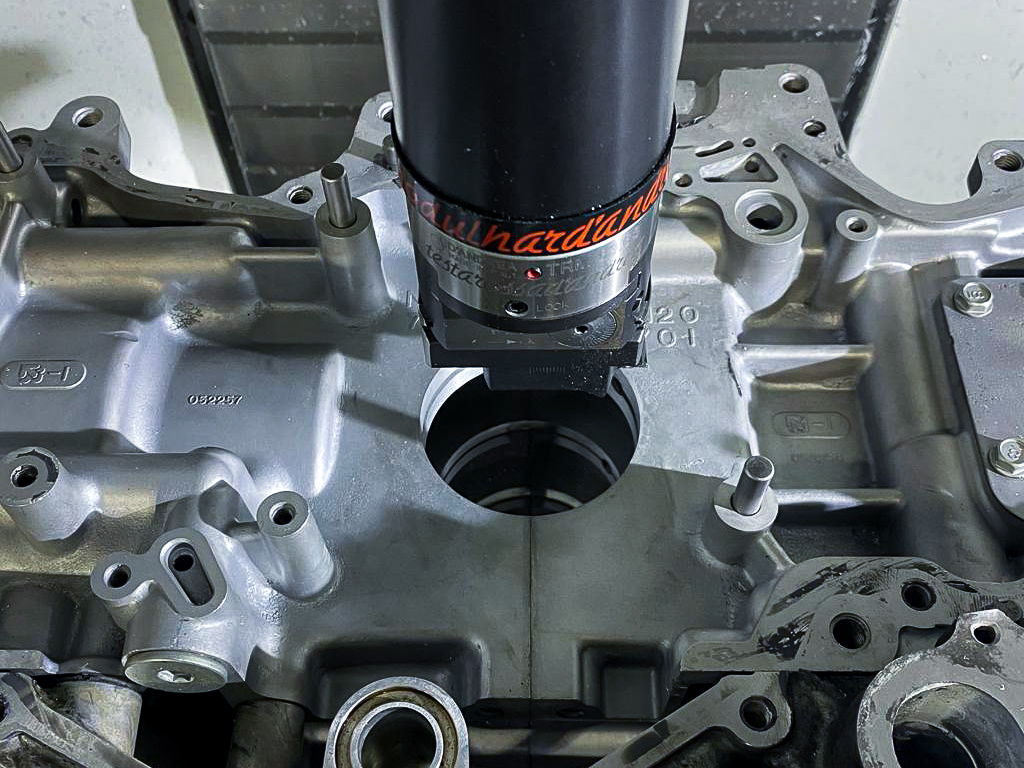

FA20 engine Line Boring service

295.00 Eur

Since FA20 engines have become more popular, we have noticed that they have similar problems as EJ engines have – the main bearing bore alignment is out of line and causes loss of oil pressure and spun rod and main bearings. Experienced engine builders will agree that line boring is the best way to correct the main bearing housing alignment and roundness.

We do vertical CNC line boring service. There are few steps involved:

1. first we remove 0,04-0,08 mm of material from each case halves;

2. bolt case halves together;

3. load the case in CNC, and level it out to 5 microns top to bottom against the CNC spindle axis;

4. line bore within a precision of 5 microns (targeted to minimal recommended bore size for best bearing crush);

5. FA20 engine case is ready for engine assembly.

This service is commonly used with other services we provide. Find more here.

Payment

Before needed services we agree on all the prices and services need to be done. The invoice is sent after all the work is completed and before the engines are being shipped. Once a payment is recieved, we ship the cases.

Shipping

Currently, we are offering shipping cases all over Europe and we use courier delivery services from door to door.

To determine the shipping cost of a product, add the product to your shopping cart, and input your shipping address. We will contact you about the final shipping cost and estimated delivery timeframe.

Thank you!

We will contact you soon!